SEO Version

I

,

J

(Q

I

2.

3.

ACCEPT

REJECT

4.

OUTLET

OUTLETS

5.

6.

OPERATION AND ADJUSTMENTS

A selector should never be oiled.

Every selector has Q permanent

mognel which lends to pick up

steel filings.

Spore units should, therefore,

be wropped or bogged.

In. case of d.iHi cu Ily, fi rst make certo in that you have refered

to the instruction

s

for you r PQrticu Ior 'Selector and then foHow

the instructions step by step.

In the event of a malfunction of the selector,

proceed as follows:

1.

Remove the sel eclo r from the vendor.

2.

Open the SCQvenger (.it is hi nged

of

the r ighl side) ond in-

spect it for cleon I iness.

If there is

the

least doubt os

10

i

Is cleanl

iness,

follow the cl eon; ng procedure out Iined in

this monual.

3.

Chec k a II screws for Ii ghtness.

4.

Stond the sel

ecter

upr; gh

t

on

0

Ievel surface and in serf

coins.

Observe whelher the coins are accepted,

rejected,

0 1

lodged in the selector.

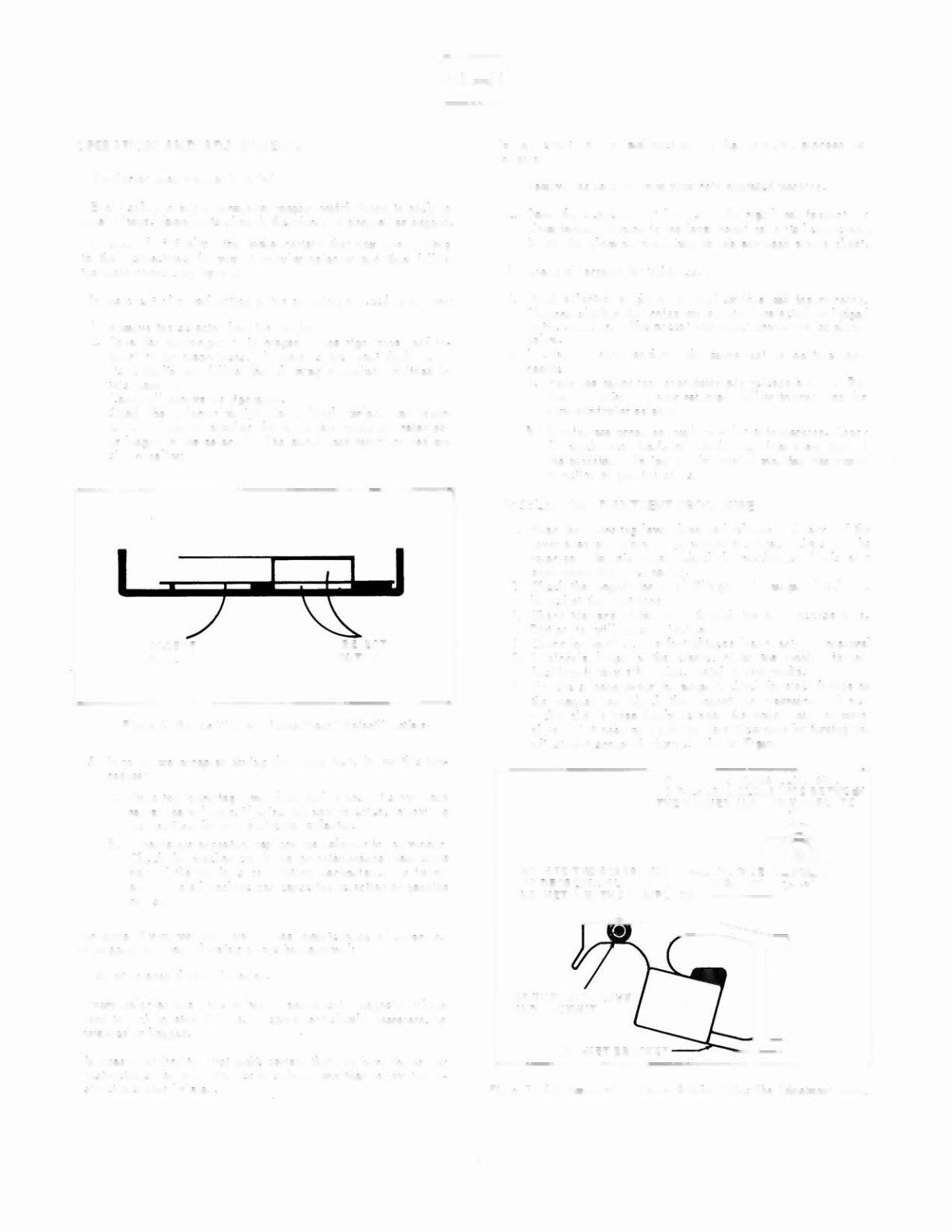

The accept ond reject chutes ore

shown below;

Figure 6.

Bottom

Viewof "Ac cept" ond "Re ;e ct" Outlets.

5.

If coins (Ire accepted during the above test, follaw this pro-

cedure:

A. Push the operating lever down and release it slawly and

relesl Ihe selector;

if cains are now rejected,

lollaw the

i nslructi ans for

ya

ur

port icular selector.

B.

If coins are accepted,

rep Iace the selector in the vendar.

Check far mechanical

binds or interference lram same

port af the vendor's co in return mechan ism.

An

i

mpre-

perly leveled machine can couse the rejection al genuine

coins.

For those af yau, wha are new

10

the maintenance af seledars,

we suggest that Ihe fallowin g pal nts be observed;

A sel ectar shou Id never be oil ed.

Every selector has one

or mere

permanent

magnets which

tend to pick up steel Ii Iings.

A spare un it shou I

d,

therelare,

be

wrapped or bogged.

In case

01

difficulty,

first make certain that yau have the

proper

instructians

lor your particular selectorond then follow the in-

structions step by step.

In the evenl

01

a malfunction

01

the selector,

praceed as

lallows:

J.

Remove the selector Irom your coin operated machine.

2.

Open Ihe scavenger (it hinges fa Ihe right) ond inspect

for

c Ieanl iness.

If the re is the leosl douht as

10

its being c Ieon,

lollaw the cleaning procedure on the enclosed single sheet.

3.

Check all screws for tightness.

4.

Stand se Iector u

prl

gh t on

a

leve I surface and insert cains.

Observe whether the coins are accepted,

rejected Or lodged

in the

seleeror.

The accept and reject chutes are as shawn

below:

5.

If coins are accepted during the nbove lest, follow this

pro-

cedure:

A. Push the opera ling lever down and release slowly.

Re-

test.

If coins are now reiec:ted.

fallow instrucfions for

your particular selec.tor.

6.

If coins ore accepted,

replace selectar in machine. Check

for mechanical

binds or interference from some port of

the machine.

An imp.roperly l<1veled machine can cause

rejecti on of gen u ine ca in s.

501

SELECTOR ADJUSTMENT PROCEDURE

1.

Push the aperoting lever down and

rel

ease it slowly.

If the

l<1ver does not relurn to its normal po s

i

tion, ni eke Iswill

be

rejected.

In this event,

check for .mechanical

binds or a

weak operating lever spring.

Check the magnet far steel filings.

The magnet bracket is

hi nged at the ri ght si de.

Check the face of the anvil Ihraugh the anvil access hal e.

Dirt or lint will couse rejection.

Check the anvil screws far tightness (use plenty of pressure).

If n icke Is lodge

j

n the cradle,

cI eon the crodl e pin and

bush iog; if Ihey sf;

II

lodge, inslol J

a

new cradle.

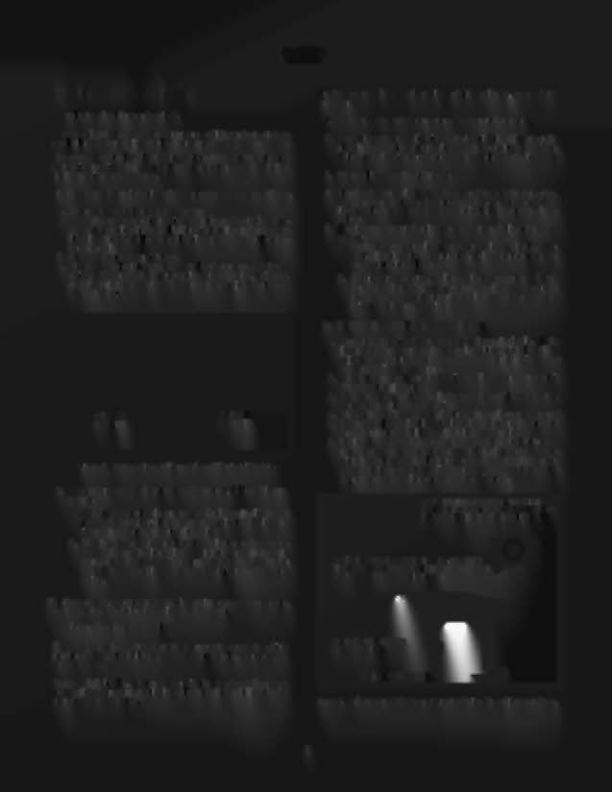

If nickel s lodge un der the magnet, check for steel fi lin gs on

the magnet and check the magnet for cleo ron

Co l.

A new

nickel shauld pass freely hetween the magnet

end

the main·

plate.

If it does not, provide more clearance by turning the

adjustment

screw clockwise,

refer to Fi gure

7.

ROTATE THE SCREWCLOCKWISE

TO INCREASE CLEARANCE BETWEEN

THE MAGNET AND THE MAINPLATE

~

ROTATE THE SCREWCOUN.TER.CLOCKW1SEGJ

TO DECREASE CLEARANCE BETWEEN THE /-

MAGNET AND THE MAINPLATE

Figure 7. Ad;us·'meM' of

the

Magnet

Bracket

U.sing Tbe Acliustment Screw.

2

Powered by FlippingBook Publisher