SEO Version

For those of you, who are new to the maintenance of slug rejectors, we suggest that

the following points be observed:

A slug rejector is never oiled.

Every slug rejector has one or more permanent magnets which tend to pick

up steel filings. A spare unit should, therefore, be wrapped or bagged.

In case of difficulty, first make certain the you have the proper instructions

for your particular rejector and then follow the instructions step by step.

In the event of a malfunction of the slug rejector. proceed as follows:

1. Remove the rejector from your coin operated machine.

2.

Open the scavenger (it hinges to the left) and inspect for cleanliness.

If

there is the least doubt as to its being clean, follow the cleaning proce-

dure on the enclosed single sheet.

3.

Check all screws for tightness.

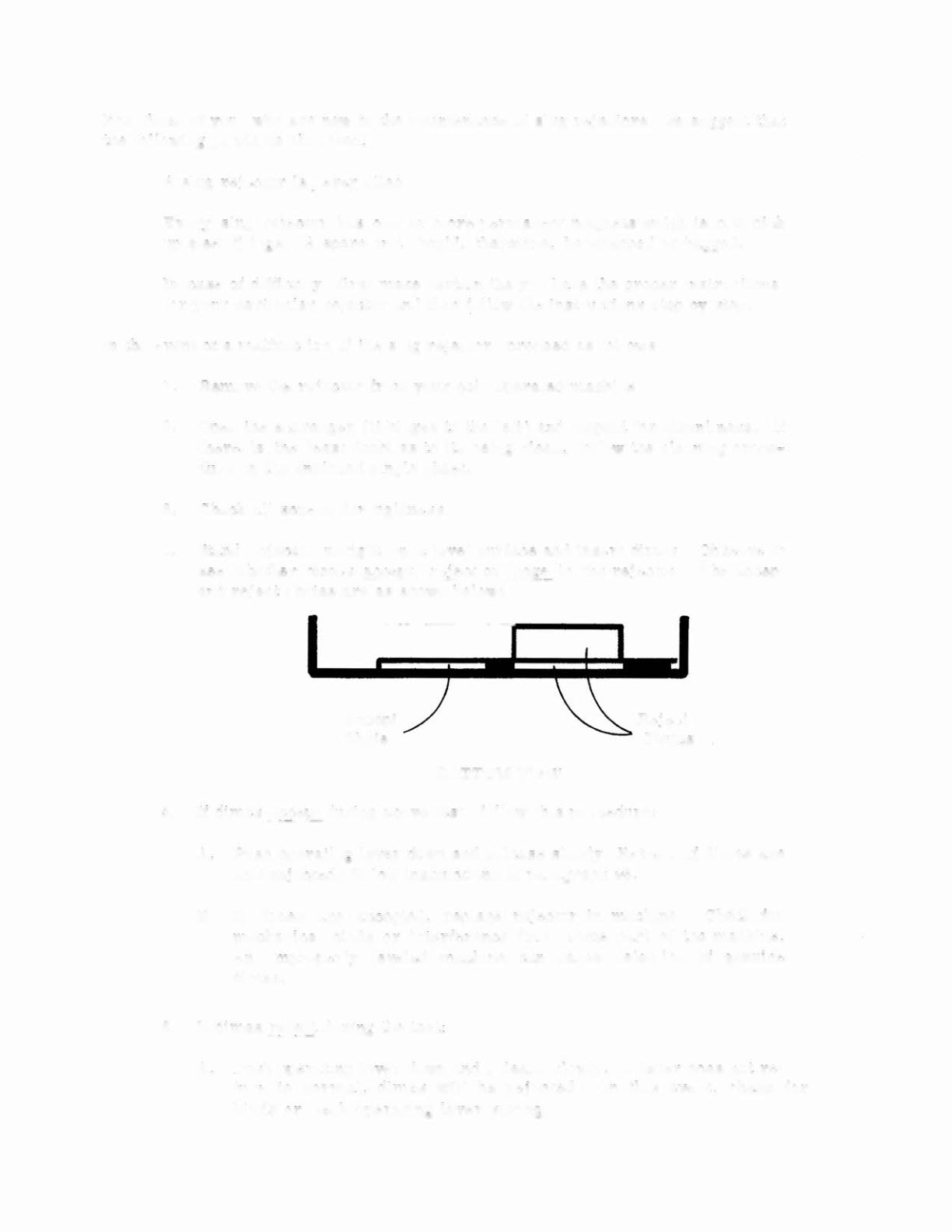

4. Stand rejector upright on a level surface and insert dimes. Observe to

see whether dimes acceet, reject or ~ in the rejector.

The accept

and reject chutes are as shown below:

Accept

Chute

BOTTOMVIEW

5. If dimes acceet during above test, follow this procedure:

A. Push operating lever down and release slowly. Retest. If dimes are

now rejected, follow instructions in paragraph #6.

B. If dimes are accepted, replace rejector in machine.

Check for

mechanical binds or interference from some part of the machine.

An improperly leveled machine can cause rejection of genuine

dimes.

6. If dimes reject during the test:

A. Push operating lever down and release slowly. If lever does not re-

turn to normal, dimes will be ' rejected.

In this event, check. for

binds or weak .operating lever spring.

Powered by FlippingBook Publisher